More and more frequently both historical and current elite unit badges and insignia, as well as rare historical badges are being counterfeited and appearing on the military badge collectors market, realizing exorbitant prices, hundreds of dollars/pounds having literally gravitated into the thousands. This fact is being exacerbated by the fact that previously highly reputable dealers and militaria auction houses are experiencing having their “experts” fooled by the quality being achieved in the fraudulent badges, or have allowed their past diligent venting standards diminish, or a combination of both factors. These facts have resulted in a significant frustration level permeating the entire collector population, and in the extreme case people, ceasing to add to their collection, or divesting and leaving the hobby altogether. In either instant this is not only detrimental to the overall hobby, but to the continued livelihood of the dealers and auction houses.

The use of scanning electron microscope (SEM) technology as “one tool” in forensically evaluating authenticity of badges has been recognized for some time. Until recently the invasive specimen selection process (apparently now eliminated), combined with the high price of the capital equipment, $0.5mil USD to $1.0mil USD and a trained microscope specialist, has virtually precluded the practical development and application of this technology in a broad, cheap, definitive, and convenient forensic method. In addition, by no means does it provide a definitive comprehensive verification What it does supply is a significant additional investigative tool.

In a very recent post on the British and Commonwealth Military Badge Collector’s Forum, a member, Wayne Logus, has presented a “proof of concept” for this truly forensic analysis technology which assists in determining whether a metal cap badge is genuine or counterfeit. With full acknowledgement of his effort, and expression of gratitude for his kind permission, the results of his study are herein presented.

“Can Science help distinguish replica, metal-made collectables?

Apologies for the long post.

I would like to present to fellow collectors, an experiment I undertook at our local university this week. The purpose was two-fold; 1) to establish a “proof-of-concept” for using SEM-EDX to adequately identify the elemental composition of a collectable, metal insignia and, 2) to use this same technique to try to determine that, if by looking at the elemental composition, one might be able to determine replica or “fake” items within the vast field of collectables. To demonstrate the later, I choose to look at one of my collecting interests, the CAF (Canadian Air Force) insignia circa 1920-1924. They are uncommon enough that one generally doesn’t come across a large selection so collectors may only see these in isolation at shows, dealer’s stores, online or auction houses and at times, it can be very difficult to know if an item is truly an authentic, original, period piece or not. As we all know, it’s getting harder as the fakes and fakers get better.

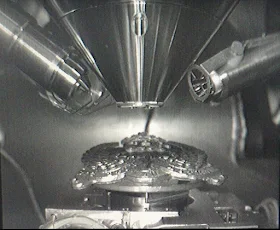

The Zeiss-EVO SEM-EDX (Scanning Electron Microscope with Energy Dispersive X-ray) is an instrument which, beyond incredible imaging capabilities, allows materials research and analysis which can provide quantitative*, elemental identification. In my case, I was primarily interested in the later for my insignia not the imaging capabilities so coating of the samples wasn’t required and the technique is non-destructive; i.e., you get your stuff back intact and unaltered! The scientist who ran this instrument during my session was very knowledgeable, helpful and pro-active with suggestions (thanks Nathan).

Over the last few years, I have picked up several examples of the enlisted, Type 2 (with motto) versions of CAF collars which have had an unexpected crown for the issue. Unusual in the sense that it has the larger void shape normally reserved for Officer’s more complex, multi-component badges. Enlisted versions have a small void in the crown and are basically two-piece; a CAF monogram fitted over a die stamped body and fastened in place by a pin through the center then riveted to the back of the badge. Could there have been errors during assembly, some variant that hadn’t been reported or were they modern replicas?

The first two images below illustrate an original collar on the left and the questionable copy on the right. I’ve highlighted a few differences to note between the two. The lack of detail on the reverse of the replica is a give-away – if you know what to expect. Four additional variations are shown, each with a slightly different finish but by using the SEM-EDX, they show a wide variety of elemental compositions. The top left example is very interesting as it is mainly an alloy of tin with some lead. The finish is from an aluminum powder coating or paint and there is a high percentage of Cd, Cadmium in the piece, a toxic compound often found in off-shore costume jewelry. The top right example is basically made from a 50/50 solder of Pb-Sn (lead-tin) composition.

The original enlisted versions of cap and collar CAF insignia have an elemental composition of primarily Copper, Nickle and Zinc often called “German” metal. Based on initial measurements of several period pieces of CAF cap and collars, they all exhibit similar ratios in their major elemental components.

To illustrate the EVO’s output, a rough graph and semi-normalized elemental weight% values of one replica piece is illustrated. Further calculations and assumptions to normalize all readings were required to give a final “quantitative” estimate of the various elements present. The microscope doesn’t analyze the entire badge; only a very small, sub mm portion selected by the user and chosen to be representative of the object under study. The area is selected to be “clean” from surface contaminants; oxidation, sulfonation, the initial organic lacquer applied to these insignia to help preserve luster, grease and dirt, etc.

One of many interesting side observations that came out of this study was that at least some original enlisted CAF monograms had a trace of surface silver plating presumably to highlight that component. The low res SEM image shows the valleys and ridges on the top of the “A” in the CAF monogram. Visually through the SEM eye, one can observe a difference in the composition as demonstrated by a shade and texture variation and further borne out in the analysis at the points of the barely visible, green, overlaid numbers 2 and 3. The lower recessed layer contained regions indicated at over 95% silver while the majority of the monogram was the same composition as the main insignia. This suggests a very light silver coating on the NCO monograms which has worn off on the higher relief regions; more sampling of different pieces would be required to confirm this as a general statement. Also noted in passing is that the monogram pin is composed of 100% copper, probably because it was easy to solder onto the monogram and easy to rivet to the body of the badge.

I was also able to briefly look at some replica CAF pilots wings (I have four, clearly different replica variations but all possibly formed from the exact same duplicated die). This will be discussed perhaps in a submission to the MCCoC Journal down the road.

Other collectable areas such as fine art, stamps and sports memorabilia have respected recognized experts, technology and organizations where one can send their rare and valuable items for authentication and certification. Perhaps it’s time our field offered such a service too? Maybe this instrument will play a role in that in the future.

Regards,

Wayne Logus”

Wayne has well defined what this level of forensic analysis can do, however there are limitations to what scope and extent of proof it can and cannot provide. Here are some of the limits;

The repeatability, i.e. consistency, of the readings on multiple samples taken from different locations on the rear of the same badge were shown to be at or around the 95% level.

The size of the samples achieved to date are well below the size required for that required for a mathematically established statistical sample.

The variability of the metallurgical composition between production runs by a single manufacturer over time, or between different manufacturers has not been established.

Wayne has cited the cost at around $65.00/hour with the ability to analyze six badges in the span of an hour. So, a collector must make a cost effectiveness decision on the expenditure.

As was previously stated the methodology provides an additional weapon in the arsenal against counterfeiters. Combined with the other weapons in that arsenal it provides an additional element of defense for collectors. It would be much to their credit if on particularly high-end rare/unique items, dealers and auction houses would incur the expense and include an analysis certificate with the item.

No comments:

Post a Comment